Table of Contents

- Introduction

- Understanding Italian Marble and Engineered Surfaces

- Aesthetic and Design Flexibility

- Structural Strength and Surface Performance

- Consistency, Sizing, and Installation Considerations

- Maintenance, Repair, and Lifecycle Factors

- Sustainability and Environmental Impact

- Cost Implications and Long-Term ROI

- Material Selection for 2026 Architectural Projects

- Conclusion

- FAQs

1. Introduction

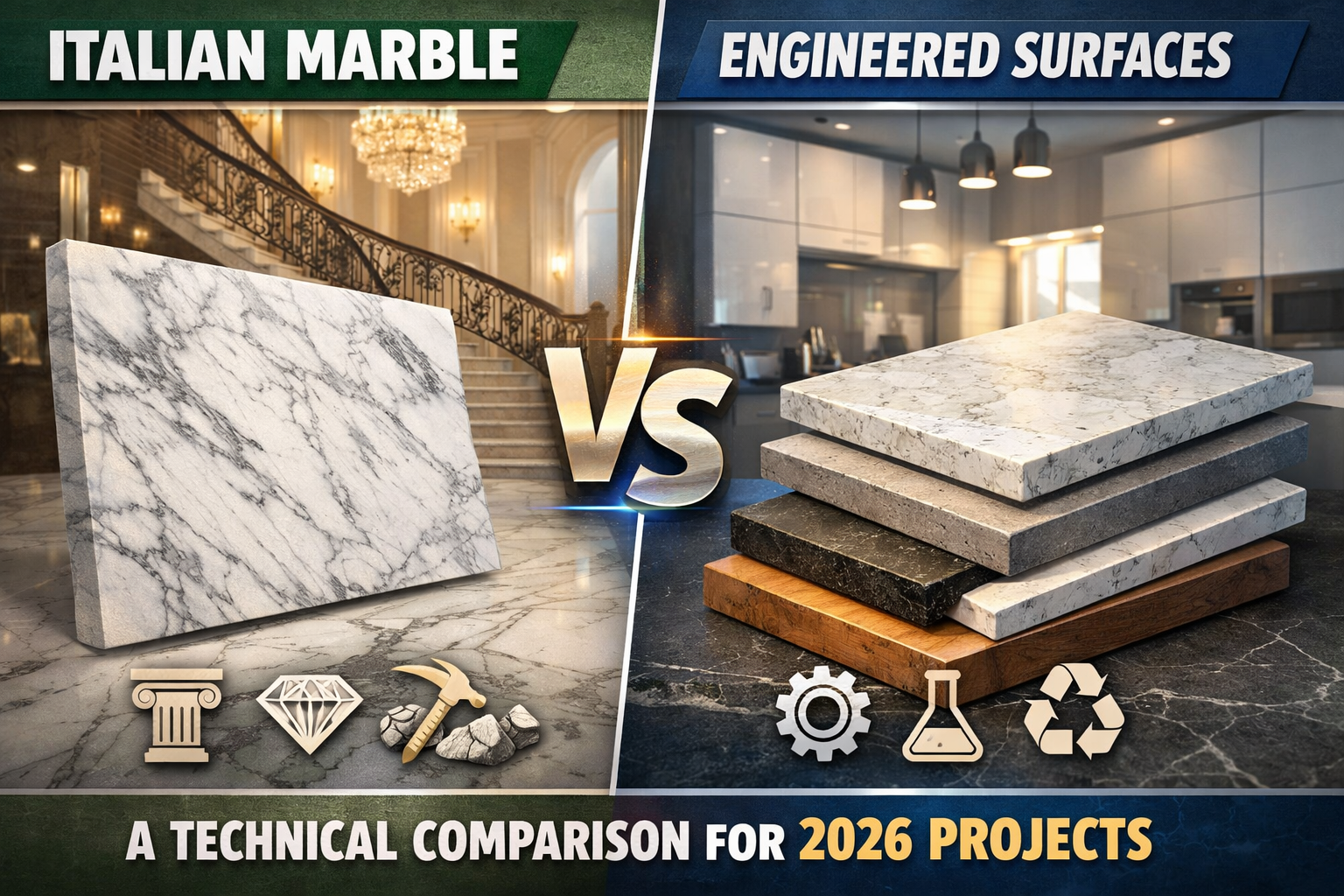

As architectural projects evolve in 2026, material selection is becoming increasingly technical. Designers, architects, and builders are no longer choosing surfaces based only on appearance. Performance, lifecycle value, sustainability, and installation feasibility are equally important.

Two materials often compared in modern construction are natural Italian marble and engineered surfaces such as quartz, sintered stone, and composite slabs. This article presents a technical comparison to help professionals choose the right material for high-end projects.

2. Understanding Italian Marble and Engineered Surfaces

Italian marble is a natural stone formed over millions of years under geological pressure. It is quarried, cut into slabs, and polished for architectural use. In contrast, engineered surfaces are factory-made using crushed minerals, resins, and pigments pressed into slabs under controlled conditions.

Because of its natural origin, Imported Italian marble carries unique veining and texture, while engineered materials offer uniformity and predictable patterns.

3. Aesthetic and Design Flexibility

From a design perspective, Italian marble offers unmatched visual richness. No two slabs are identical, allowing architects to create signature spaces using book-matching and vein continuity techniques.

Engineered surfaces, while consistent, often repeat patterns due to manufacturing limitations. This can reduce the exclusivity of high-end interiors.

Neutral tones such as Italian grey marble in India are frequently specified in luxury projects because they harmonize effortlessly with modern materials like glass, wood, and metal without overwhelming the design language.

4. Structural Strength and Surface Performance

Engineered surfaces are known for high scratch resistance and low porosity due to resin bonding. However, they can be sensitive to high temperatures and may discolor over time.

Italian marble, though slightly more porous, offers superior heat resistance and compressive strength. It remains stable under varying climatic conditions, making it ideal for both flooring and wall applications.

Additionally, marble ages gracefully, developing a natural patina, whereas engineered surfaces may lose their original finish with wear.

5. Consistency, Sizing, and Installation Considerations

One advantage of engineered surfaces is size uniformity and minimal thickness variation. This simplifies installation in modular projects.

However, advancements in processing now allow Premium Italian marble slabs to be supplied in large formats with calibrated thickness, enabling seamless installations in expansive spaces such as hotel lobbies and corporate offices.

Italian marble also allows for on-site polishing and refinishing, which is not possible with pre-finished engineered materials.

6. Maintenance, Repair, and Lifecycle Factors

Engineered surfaces are marketed as low-maintenance, but once damaged, they are difficult to repair invisibly. Chips, burns, or deep scratches often require slab replacement.

Italian marble, on the other hand, can be re-polished multiple times over decades. This makes it highly sustainable from a lifecycle perspective. Proper sealing ensures easy maintenance and stain resistance.

For this reason, many professionals consider Italian marble for builders a more practical choice for projects that demand longevity.

7. Sustainability and Environmental Impact

Sustainability is a key consideration in 2026 projects. Engineered surfaces involve industrial processing, resin use, and energy-intensive manufacturing.

Italian marble requires quarrying and cutting but minimal chemical processing. Being a natural material, it has a lower synthetic footprint and can be recycled or repurposed at the end of its life.

This natural origin aligns better with green building concepts and eco-conscious architectural practices.

8. Cost Implications and Long-Term ROI

At first glance, engineered surfaces may appear cost-effective due to lower upfront pricing and standardized supply. However, when considering lifespan, refinishing ability, and aesthetic longevity, Italian marble often provides better value.

Working with the Best marble company in India ensures correct grading, selection, and supply consistency, which reduces wastage and enhances overall project efficiency.

9. Material Selection for 2026 Architectural Projects

For high-end residences, hospitality spaces, and premium commercial environments, Italian marble offers uniqueness, prestige, and durability. Engineered surfaces may still be suitable for kitchens, laboratories, or utility areas where uniformity and stain resistance are primary concerns.

The choice ultimately depends on the function of the space, design intent, and lifecycle expectations.

10. Conclusion

Both Italian marble and engineered surfaces have their place in modern architecture. However, when the goal is to create timeless, luxurious, and high-value spaces, Italian marble continues to lead. Its natural beauty, structural reliability, and long-term performance make it a preferred specification for 2026 projects.

11. FAQs

Q1. Is Italian marble more durable than engineered surfaces?

Italian marble offers excellent heat resistance and can be refinished, giving it a longer practical lifespan.

Q2. Are engineered surfaces completely maintenance-free?

They require low maintenance but are difficult to repair if damaged.

Q3. Which material is better for luxury interiors?

Italian marble is preferred for its natural beauty and exclusivity.

Q4. Can Italian marble be used in large commercial spaces?

Yes, large slabs and consistent finishes make it suitable for expansive installations.

Q5. How does sustainability compare between the two materials?

Italian marble has a more natural lifecycle with less synthetic processing involved.