Table of Contents

- Introduction

- Evolution of the Marble Processing Industry

- Advanced Quarrying Technologies

- Role of Automation in Marble Processing

- Precision Cutting and Finishing Innovations

- Digital Quality Control and Inspection

- Sustainable and Eco-Friendly Processing Technologies

- Technology-Driven Customization and Design

- Impact of Technology on the Global Marble Market

- Conclusion

- FAQs

1. Introduction

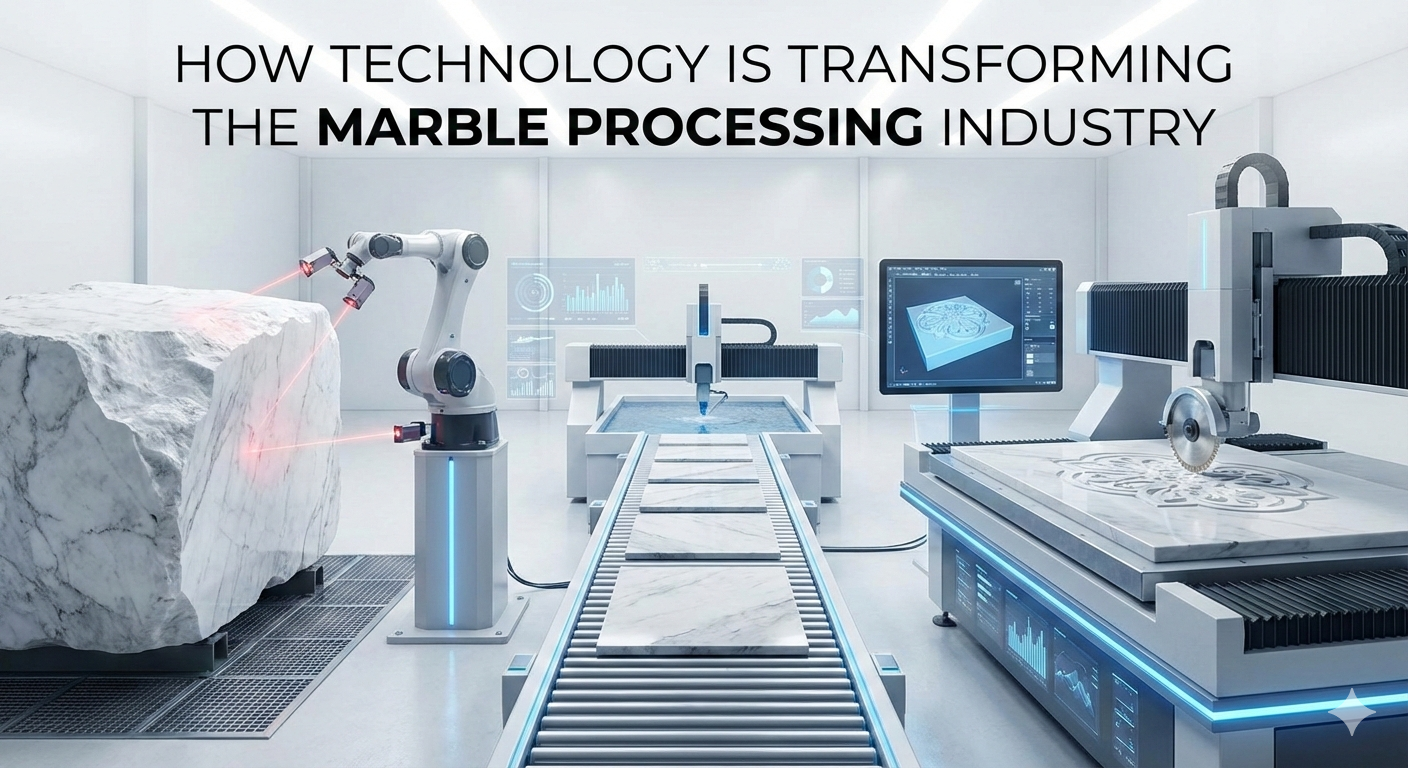

The marble industry, once driven largely by manual labor and traditional techniques, is undergoing a remarkable transformation. With the integration of modern technology, marble processing has become more precise, efficient, and sustainable than ever before. From quarrying to polishing, advanced machinery and digital tools are redefining how marble is extracted, processed, and delivered to consumers.

This technological shift is not only improving product quality but also enabling marble suppliers to meet the growing global demand for premium and customized stone solutions.

2. Evolution of the Marble Processing Industry

Traditionally, marble processing relied heavily on manual cutting, basic equipment, and skilled craftsmanship passed down through generations. While these methods created beautiful results, they were time-consuming, labor-intensive, and prone to inconsistencies.

Today, the industry has embraced innovation to overcome these limitations. Modern processing units now combine craftsmanship with cutting-edge technology, ensuring superior accuracy, faster production, and consistent quality across large volumes.

3. Advanced Quarrying Technologies

Technology has significantly improved the way marble is extracted from quarries. Modern quarrying methods focus on minimizing waste while preserving the natural integrity of the stone.

Key advancements include:

- Diamond wire cutting for precise block extraction

- Controlled blasting techniques to reduce fractures

- GPS-based quarry mapping for efficient resource utilization

These innovations ensure that marble blocks are extracted with minimal damage, resulting in higher-quality raw material for processing.

4. Role of Automation in Marble Processing

Automation has become a cornerstone of modern marble processing plants. Fully automated production lines now handle tasks that once required extensive manual effort.

Benefits of automation include:

- Faster slab production

- Reduced human error

- Uniform thickness and surface quality

- Improved workplace safety

Such automation enables large-scale operations to maintain consistency, making it easier for suppliers to meet international quality standards.

5. Precision Cutting and Finishing Innovations

One of the most significant technological advancements in marble processing is precision cutting. CNC (Computer Numerical Control) machines and multi-blade gang saws allow for highly accurate slab cutting.

These machines make it possible to process premium stones such as Michelangelo marble in India with exceptional precision, preserving intricate patterns and natural beauty.

Advanced polishing lines further enhance surface quality, delivering finishes that are smoother, glossier, and more durable than ever before.

6. Digital Quality Control and Inspection

Quality control has evolved from visual inspection to digital evaluation. Modern processing units use high-resolution scanners and software to assess marble slabs for:

- Color consistency

- Vein distribution

- Structural integrity

This technology ensures that each slab meets strict quality benchmarks before reaching the market. As a result, stones like Italian grey marble in India are delivered with uniform appearance and superior finish, even across large projects.

7. Sustainable and Eco-Friendly Processing Technologies

Sustainability is becoming a key focus in the marble industry, and technology plays a vital role in reducing environmental impact.

Modern processing plants now use:

- Water recycling systems to reduce consumption

- Energy-efficient machinery

- Dust suppression and waste management technologies

These practices not only lower operational costs but also align the industry with global environmental standards, making marble processing more responsible and future-ready.

8. Technology-Driven Customization and Design

Technology has opened new possibilities for customization in marble applications. Digital design tools allow architects and designers to visualize layouts, book-match slabs, and plan installations before actual processing begins.

This level of customization is particularly valuable for luxury projects using statement stones like Statuario marble in India, where precise pattern alignment is critical to the final aesthetic outcome.

Clients now receive tailor-made marble solutions that perfectly align with their design vision.

9. Impact of Technology on the Global Marble Market

Technological advancements have significantly enhanced the global competitiveness of marble suppliers. Faster production, consistent quality, and reliable logistics have enabled suppliers to serve international markets more effectively.

Leading players in the industry—often recognized as the Best imported marble supplier in India or the Best marble company in India—leverage technology to maintain high standards, ensure transparency, and deliver value to customers worldwide.

This transformation has positioned marble as a premium yet accessible material for modern architecture.

10. Conclusion

Technology has revolutionized the marble processing industry, turning a traditionally labor-intensive sector into a highly efficient and precision-driven operation. From quarrying and cutting to finishing and quality control, every stage of marble processing has benefited from innovation.

As technology continues to evolve, the industry is set to achieve even higher levels of quality, sustainability, and customization. For architects, designers, and homeowners, this means better marble, smarter choices, and timeless results.

11. FAQs

Q1. How has technology improved marble quality?

Technology ensures precise cutting, uniform thickness, and better surface finishing, resulting in higher-quality marble.

Q2. Is automated marble processing more expensive?

While initial investment is higher, automation reduces waste and labor costs, making it cost-effective in the long run.

Q3. Does technology help in sustainable marble processing?

Yes, modern technologies significantly reduce water usage, energy consumption, and material wastage.

Q4. Can technology customize marble designs?

Absolutely. Digital tools allow precise layout planning, book-matching, and customized finishes.

Q5. Will technology replace traditional craftsmanship in marble processing?

No. Technology complements craftsmanship by enhancing precision and efficiency while preserving the natural beauty of marble.